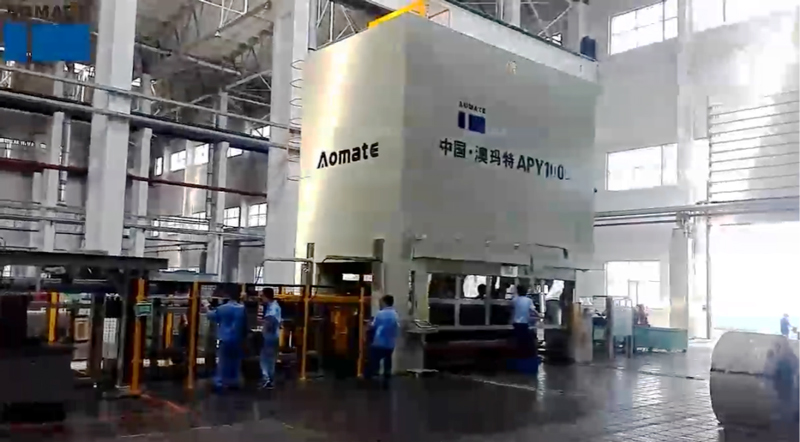

Volkswagen's seat slide rail production line uses Aomate's APY-1000 closed two-point split-type precision power press with an automatic de-stacking unit. It ensures precise lubrication, material delivery, and high-speed transmission in multi-position dies, meeting stamping production requirements with strong rigidity for thick plate forming.

Adopting Aomate APY-1000 closed two-point split type precision power press, with an automatic de-stacking unit, the sheet is precisely lubricated, and the material is quickly and accurately delivered to the designated position, and then the high-speed transmission in the multi-position die is completed through the three-dimensional servo mechanical arm to meet the various stamping production process requirements. The power press adopts the structure of a three-stage body + reinforcing rod to ensure the strength and rigidity required for thick plate forming. According to the assembly accuracy requirements of automobile main engine manufacturers, diversified development and production lines are equipped; It fully proves the strong R & D team and customized service concept of Aomate.

It is widely used in the main automobile engine factory and the body structure, support and body accessories of the first-class stamping parts suppliers.

29 Canglongshan Road, Beilun District, Ningbo City, Zhejiang Province, China

sale01@aomate.com.cn sale02@aomate.com.cn

+86 574 8611 3500

+86 574 8611 3519

Copyright © Ningbo Aomate High Precision Power Press Co., Ltd. All Rights Reserved Sitemap

| Powered By